The History of Aero

We are proud of our more than 100-year history. Read about the creation of a legendary aircraft, and how the company operated during historical milestones.

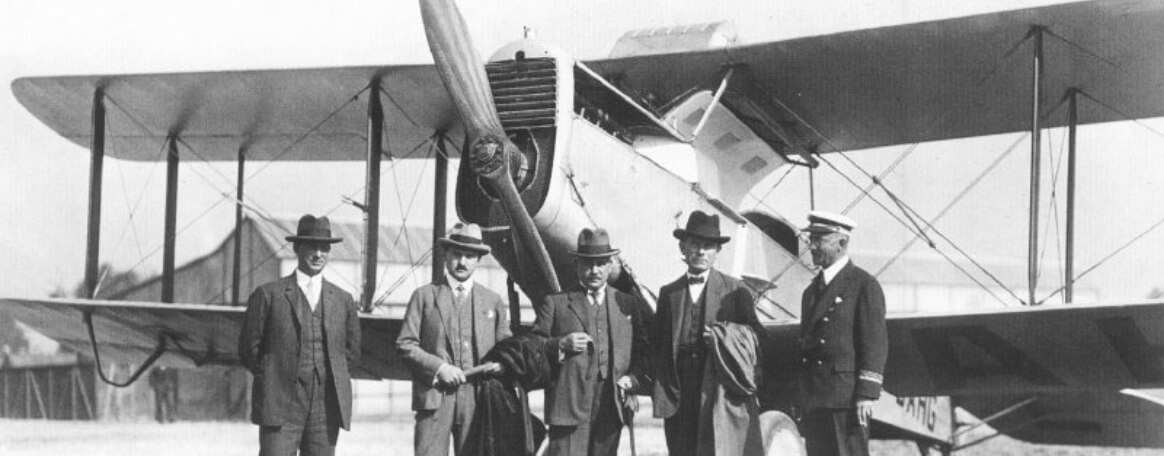

The beginnings. 1919 - 1921

The history of Aero began on the 25th of February 1919, just a few months after the creation of independent Czechoslovakia.

The new company, which focused on the production of aircraft and aircraft parts, as well as aircraft repairs, was soon followed by two more companies – state-owned enterprise Letov and private company Avia. However, for a long time Aero was the strongest of these three companies, both in terms of labour force and in production volume.

1919

Aero A-1, the first military aircraft of its own design. The A-1 was designed for a two-man crew – a pilot in the front cockpit and an observer (or instructor) in the rear. In 1919, the Ministry of National Defence ordered 35 such machines for the Czechoslovak Army for pilot training. The first flight, with pilot Rudolf Valenta, took place 49 days after the signing of the contract.

The aircraft was built under the direction of the designer Antonín Vlasák.

At the same time, Antonín Husník joined Aero as chief designer. He was a co-founder of the Czechoslovak Aeroclub and participated in the creation of the Czechoslovak Air Force. Vlasak and Husnik together prepared the design of the first purely Czech fighter aircraft Ae-02. It first flew in 1920, but did not impress the Czechoslovak Air Force. The following year, however, this machine, piloted by Josef Novák, won the Aeroclub Silver Cup (1st place in the aerobatic category and 2nd place in the speed category). These successes encouraged Aero to develop other types.

1922

A-10, the first civilian transport aircraft of its own design. The design was based on the A-8 type. The two-man crew had to brave the elements in the open cockpit, while the five passengers below enjoyed the relative luxury of an enclosed cabin. The five machines were operated by Czechoslovak Airlines and were deployed on the Prague-Bratislava route from October 1923.

In addition to these successful types, several other military reconnaissance and training aircraft were developed. Among them was the A-14. Five of these aircraft served as biplane training machines, while 20 others were built as reconnaissance aircraft. Seventeen aircraft were modified for commercial airline operations.

Other types followed, some of which ended up in the project or prototype phase.

At this time, many prominent personalities worked alongside Antonín Husník, such as Otto Wels, who was succeeded by Antonín Slavik.

Expansion. 1923 - 1938

A year after its foundation, Aero began building a factory on a green field in Vysočany, and it moved there in 1923. The company began manufacturing other types of aircraft, and became the main supplier for the Ministry of Defence and the Ministry of Public Works (civil aircraft). Deliveries to foreign countries such as Finland soon followed, too.

1923

A-11, a family of successful military biplanes (bombers and reconnaissance). The A-11 was a light bomber and observation aircraft produced in the 1920s. Approximately 250 were built. Its derivative versions were still in service with the Czechoslovak Army at the outbreak of World War II.

1925

The De Havilland DH-50, a transport aircraft manufactured under British licence.

1927

The A-32 model flew for the first time. This observation aircraft and light bomber served in the Czechoslovak and Finnish air forces. The Finns purchased 16 of two versions as a light attack aircraft, but mostly used them as trainers until they were retired in 1944.

A-35, the first mountain plane developed at Aero – later converted to a 5-passenger transport aircraft. Bata Shoe Factory purchased 2 machines for passenger and cargo transport. They were among the first corporate aircraft in the world. It was also used by CSA until 1936 in a number of 7 units. It flew in the Yugoslav Royal Air Force until the beginning of World War II.

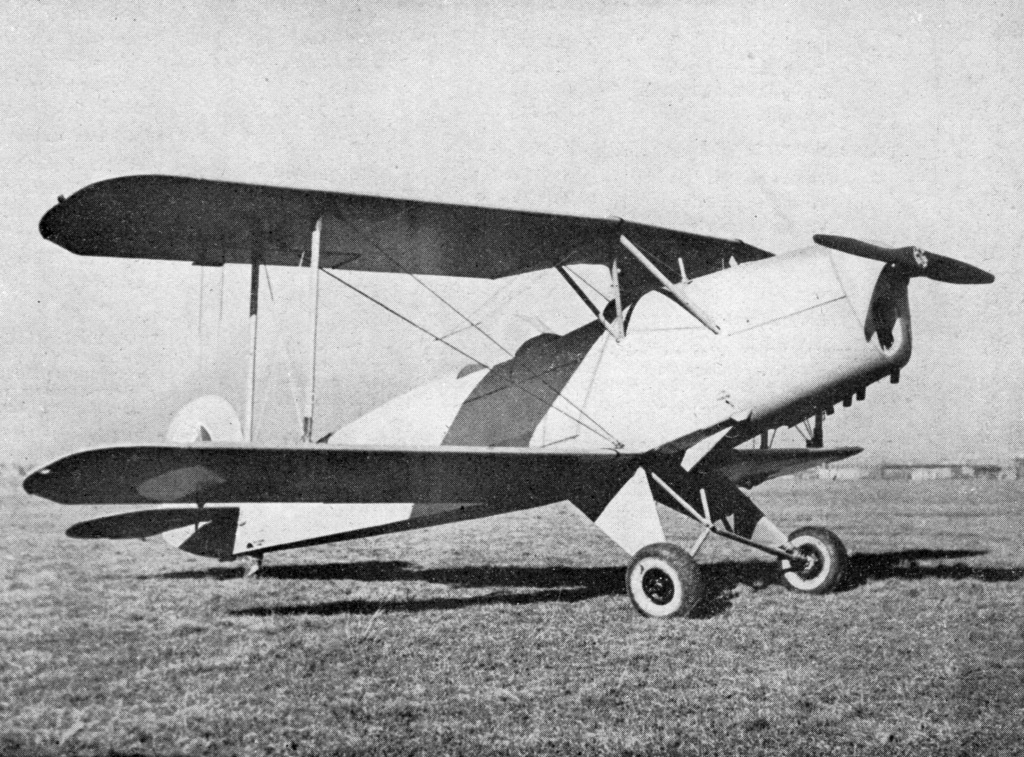

1928

The A-34 “Blackbird”, the first of a family of light sports and training biplanes

1932

A-100, in response to a request by the National Defense Department to replace all older light bombers and reconnaissance aircraft, Aero redesigned the single-engine A-430 biplane to the A-100 model. The Air Force took delivery of 44 units, which were in service until the eve of World War II. The later model A-101 was equipped with a more powerful engine.

1937

MB-200, all-metal bomber made under French license (Marcel Bloch). Followed by the new A-204, which was followed by the A-300. The beginning of World War II ended its development.

1938

A-304, a twin-engine, low-flying military aircraft based on the A-204.

After the German occupation of Czechoslovakia, A-304s were used by the Wehrmacht for crew training and transporting courier shipments and personnel.

During the occupation, development of the aircraft ceased. Local aircraft factories were forced to produce German aircraft.

War production. 1938 - 1945

During the Second World War, Aero lost all hope of continuing its own development. Instead, it had to mass produce German aircraft.

1939

Bücker – Bü31 Jungmann – training and aerobatic biplane – From the end of 1939 to September 1940 Aero produced 200 Bü-131 Jungmann training biplanes. After the war, another 240 were built until production ended in 1949.

1943

C-3 and Siebel Si-204D, a twin-engine military aircraft – Aero assembled 136 twin-engine transport and trainer aircraft of this type between March and December 1943. From 1944 onwards, the Si204D-3 model was produced, and after the war it was decided to continue production of the Si204D, both in military and civilian versions, which were designated C-3 and C-103.

Aero produced 120 complete aircraft and a similar number of fuselages for the MNO. The Bü131 also returned to production and a total of 260 were produced. The last delivery took place in 1949. Initially the aircraft bore the designation C-4, after remotorization C-104.

Post-war production. 1945 - 1958

After the end of the war, Aero wasted no time in developing a new aircraft. The four-seat, twin-engine Ae-45 was a great success.

1947

The Ae-45, a twin-engine civilian aircraft made its maiden flight. The first production version of this classic model was produced between 1948 and 1951. A total of 200 examples were produced by Aero. This was followed by an improved version, the Aero 45S Super, produced by LET in Kunovice between 1954 and 1959, with a total of 228 units. The remotorized model was produced in the same factory in 1959-1962, in 162 units.

1953

Aero moved from Prague to new premises in Vodochody.

In 1953, a new facility designed for the production of jet aircraft was built in Vodochody and began operations in the same year. Production, which involved several Czechoslovak aircraft plants, focused on the large-scale licensed production of the MiG-15 and its derivative types. The MiG-19 and MiG-21 supersonic aircraft were produced at Aero during the 1960s and 1970s, blazing a trail of production capabilities for domestic jet trainer programs – the L-29 Delfín and L-39 Albatros.

1954

The MiG-15, a jet fighter aircraft manufactured under Soviet license (3,405 aircraft delivered 1954-1962).

1958

A flight of the MiG-19 Farmer, a supersonic fighter aircraft produced under Soviet license (103 aircraft delivered 1958-1962).

Licensed production of MiG aircraft was essential for several reasons. Thanks to it, by 1957 the Czechoslovak Air Force was fully equipped with jet aircraft that were reliable and had a long service life. The pieces intended for training served until 1984. More importantly, however, Aero became a manufacturer of jet aircraft, thanks to which the local designers gained the expertise and appetite to develop their own jet models.

Age of jet aircraft. 1959 - 1967

The first jet aircraft designed in Czechoslovakia was the successful L-29 Dolphin trainer, which was designed to meet the requirements of all Eastern Bloc countries. The last deliveries of the Aero aircraft were made in 1974, yet today many are in airworthy condition and many examples have found favour with civilian owners who have given them a new lease of life.

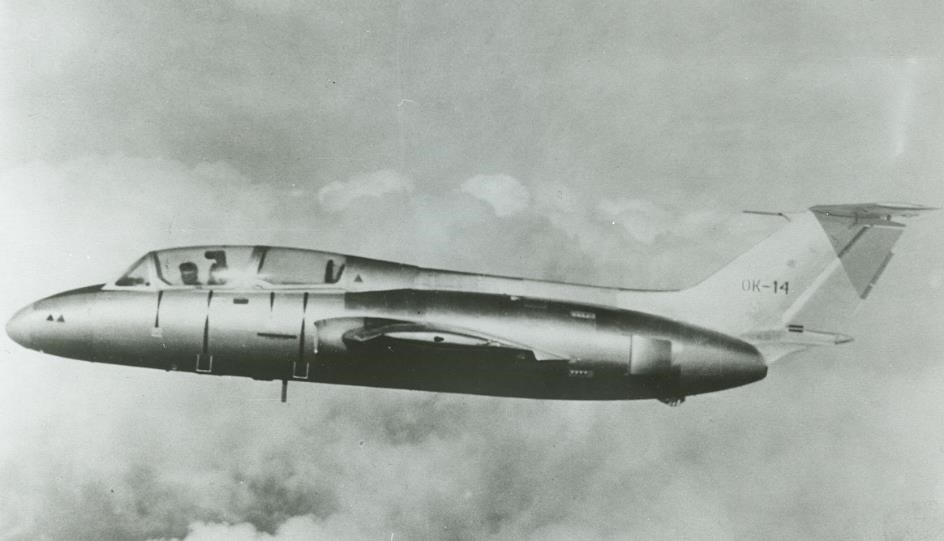

1959

XL-29 – The L-29 Dolphin prototype first flew on 5 April 1959.

A total of 3,665 L-29s were built, of which 1,943 at Aero Vodochody and the remaining 1,722 at the LET factory in Kunovice. The Dolphin thus became the most successful training aircraft ever produced. The vast majority were delivered to the Soviet Union. Others were deployed by Czechoslovakia or exported – GDR, Syria, Bulgaria, Hungary, Indonesia, Egypt, Romania, Uganda, Nigeria, China, Iraq, North Vietnam and others.

The last deliveries of the L-29 were made in 1974.

Domestic jet aircraft. 1968-1990

The L-29 was followed by the equally successful L-39 Albatros. The L-39 Albatros was the first of the second generation of jet trainers and the first with a twin-jet engine. It is still in service with many units around the world.

1968

First flight of the L-39 Albatros – The X02 prototype flew for the first time on 4 November 1968 with pilot Rudolf Duchon. It was an equally successful L-39 Albatros, with nearly 3,000 units produced for customers around the world.

Series production began and the development of the aircraft continued.

1974

At the height of the Cold War, the Soviet Union was ordering one unit after another, and production at Aero reached dizzying heights. There was a time when one airplane was produced every day.

As new variants were developed, the original version was given the name L-39C (for “trainer”). Other versions were added, such as the L-39V, L-39ZO, and L-39ZA.

1986

Flight of a jet trainer of own design of upgraded L-39 to L-39MS. The aircraft was renamed the L-59 and offered a wide range of other improvements to appeal to a wider market.

A new era. Modern combat and training system. 1992-present

The L-39 was succeeded by the more modern L-159 ALCA, the development of which began in 1992.

The return to civil production came in the form of the Ae270, which was designed as a rugged utility aircraft with a pressurised cabin (with two pilots and up to eight passengers). Although the aircraft seemed to have a bright future, given the financial situation at the time, the project was abandoned.

1997

A new era – here comes the L-159 ALCA Advanced Light Combat Aircraft.

The prototype two-seat aircraft first flew on August 2, 1997, and the single-seat one a year later on August 18, 1998.

It is a light and agile jet aircraft capable of performing a variety of missions in both civilian and military environments. It is used by the Czech army and other international customers.

The ALCA was designed to meet the Czech Air Force’s requirements for a new aircraft for direct support of ground troops and tactical attacks on ground targets. The aircraft was to be capable of playing the role of forward air control (FAC), air defence against subsonic targets and conducting tactical air reconnaissance. In addition, it was to be used for training.

More than 2 900 aircraft were delivered between 1971 and 1999.

2002

Another L-159B prototype flew for the first time on 1 June 2002. The aircraft was intended for continued, operational and weapons training.

2006

In 2006, the Ministry of Defence signed a contract for the conversion of 4 single-seat L-159s into two-seat trainers, designated L-159T1.

2017

The first export L-159T1 for the Iraqi Air Force, delivered to Balad Air Base on 5 November 2015 and the last of ten L-159s in October 2017.

2019

Aero delivered 21 L-159 aircraft to Draken. The last of them received a special desert camouflage and was delivered in June 2019.

until today

Overhauls and upgrades to both the L-159 and L-39 Albatros continue at Aero.

Resumption of jet aircraft production. 2000 - 2018

The L-39NG program was divided into two phases. The first one consisted in the incorporation of modern avionics and especially the FJ-44-4M engine into existing L-39s, while at the end of the service life of these airframes it was possible to use the powerplant in newly produced aircraft. The second phase involved the development and production of an entirely new L-39NG. The design of the L-39NG provides for continuous upgrades according to customer requirements, mainly at the level of communications and avionics systems. The avionics of the aircraft is prepared for training future pilots of the fourth and fifth generation aircraft.

2014

Aero announced the start of development of the L-39NG aircraft.

2015

The L-39NG technology demonstrator, designated as the L-39CW, first flew on 14 September 2015 with a crew consisting of factory pilots Miroslav Schützner and Vladimir Kvarda

2018

The newly produced L-39NG aircraft was presented for the first time on 12 October 2018 at the Aero factory in Vodochody. It was a big milestone for the company – 21 years since the world first saw the L-159 aircraft.

The prototype serial number 7001 with assigned registration number 0475 first flew on 22 December 2018.

Serial production of jet aircraft. 2018-present

The L-39NG has become Aero’s new flagship aircraft. It is a completely new generation of two-seat subsonic jet aircraft.

The L-39NG is a versatile platform suitable for training, reconnaissance and light combat missions.

From the flight of the first L-39NG prototype, through full certification, to the start of serial production. These are major milestones that represent a new era for our company and the future of the entire company.

2019

First public presentation of the L-39NG at NATO Days and start of serial production

2020

The successful static test of the L-39NG fuselage airframe, serial number 7002, took place in February 2020 in the Aeronautical Research and Test Institute in Prague (VZLÚ) according to the requirement of the European military EMACC regulation.

In the third quarter of 2020, the L-39NG underwent aerodynamic tests for the Light Attack version in the VZLU low-speed wind tunnel in Prague. The L-39NG prototype with serial serial number 7004 was tested by Hungarian Air Force pilots at the 59th Air Base in Kecskemét.

2021

In the first quarter of 2021, the third life cycle testing of the L-39NG demonstrated a service life of up to 15,000 flight hours, triple that of its predecessor, the L-39 Albatros.

Slovak Army pilots completed several flights with the Aero factory pilot at the Sliač base in April 2021. Pilots of the Czech Army (Czech Republic) from the 21st Tactical Air Force Base in Čáslav and from the Pardubice Airport Administration tested the L-39NG for the first time in May 2021. The first Czech military pilot in the cockpit of the L-39NG was the commander of the 213th Training Squadron Martin Pelda.

At the NATO Days in Ostrava on 19 September 2021, the L-39NG was presented to the Czech public for the first time in a dynamic demonstration.

2022

In January 2022, the third L-39NG prototype, serial number 7003, completed a fatigue test of five life cycles (five times five thousand flight hours in the hard load spectrum).

After a certification process lasting five years, the aircraft received an unrestricted type certification in 2022, which is the main prerequisite for the registration of individual aircraft with customers. The certificate, issued by the Department of Military Aviation Oversight of the Ministry of Defence, confirmed the L-39NG’s compatibility with all requirements and systems within the European Union and North Atlantic Treaty Organization countries.

A significant moment for the L-39NG jet trainer, which carries the serial number 7005, occurred on 29 November 2022. The fuselage and wing were joined together at the Aero production facility (production is being carried out separately), an important step towards the recovery and flight of each aircraft. This will be the first mass-produced aircraft in Vodochody in 20 years.

2023

In January 2023, Aero was certified to provide instruction and training on military aviation equipment, including the L-39NG jet trainer, as well as its generational predecessor, the L-39 Albatros, and the L-159 light attack aircraft.

In February 2023, Aero commissioned a new production line dedicated exclusively to the assembly of the L-39NG fuselage. Testing of the potential armament of the L-39NG trainer aircraft may take place from March 2023 at Aero’s own tunnel range at the Vodochody site.

In April 2023, the production of the L-39NG was inspected by the NATO Military Aviation Safety Working Group during its 56th meeting held in the Czech Republic.

Eastern armament trials of the L-39NG took place in April 2023 on the territory of Hungary (Pápa Air Base and the firing range near Veszprem).

The first flight (lasting approximately 40 minutes) of the series-produced L-39NG took place in April 2023 at the airport in Vodochody. The Aero pilots tested the aircraft’s functions within the scope of the standard factory sortie programme, from checking engine function to handling to aircraft behaviour in all phases of flight.

The serial production of four L-39NG aircraft for the state enterprise LOM Praha was inaugurated on 10 May 2023. The aircraft operated by the Air Training Centre in Pardubice will be used to train Czech military pilots and thus ensure the continuity of the tactical air force training on the subsonic Albatros L-39C jet aircraft. The first training aircraft produced has serial number 7029.

In May 2023, Aero opened a new development centre in Brno focused on the development of avionics systems and an interactive documentation interface for the L-39NG trainer.

International Cooperation and Aerostructures

The Aerostructures division was created at Aero in 2010 due to the need to gain a greater share of international aerospace projects, as well as to optimize specialized processes within the company. Today, Aero works with several large manufacturing companies such as Bombardier, Embraer, Leonardo, ST Aerospace, and in the past, Boeing, SAAB, Sikorsky, Spirit AeroSystems.

Since 2000, Aero has started to cooperate with a number of global aerospace manufacturers. Already in 2000, Aero started to produce the S-76 helicopter for the American company Sikorsky, a fully assembled and equipped helicopter ready for the installation of dynamic parts. Since then, Aero has won a number of other contracts for various aircraft assemblies and sub-assemblies.

In 2009, Aero signed its first-ever contract for an international risk-sharing project with the Belgian company SONACA. The subject of the cooperation is the joint development and subsequent production of a wing section (leading edge) for a completely new type of aircraft of the Canadian Bombardier – CSeries.

Two years later, Aero signed a contract with the third largest aircraft manufacturer in the world, the Brazilian company Embraer, on the basis of which Embraer and Aero became partners in the development and production of a new military transport multi-purpose aircraft KC-390.

Aero is thus involved in the development and production of the leading edge of the wing, the technological development and production of all seven doors, the ramp and the rear fuselage, which means a share in the development and production of a large part of this aircraft.

Two years later, Aero signed a contract with the third largest aircraft manufacturer in the world, the Brazilian company Embraer, on the basis of which Embraer and Aero became partners in the development and production of a new military transport multi-purpose aircraft KC-390.

Aero is thus involved in the development and production of the leading edge of the wing, the technological development and production of all seven doors, the ramp and the rear fuselage, which means a share in the development and production of a large part of this aircraft.

1997

Establishment of a joint venture with Taiwan’s AIDC to develop and produce the Ae270

1998

Boeing became a strategic partner of the company

2000

Flight of the first prototype of the Ae 270

Start of production of polished passenger door covers for the Boeing 757

Start of production of the S-76 helicopter for Sikorsky Aircraft Corporation

2001

Start of production of F-18 Super Hornet cannon doors for Boeing St. Louis

Commencement of production of Boeing 767 parts and sub-assemblies for BAE SYSTEMS

2007

Production of the middle section of the C-27J Spartan wing for Alenia Aeronautica begins

2008

Production of Embraer 170/190 door subassemblies for Latecoere started

Contract awarded for the supply of pylons for the JAS-39 Gripen aircraft for Saab.

2011

Contract signed with Embraer of Brazil for the development and production of the wing leading edge and for the technological development and production of all doors, cargo ramp and rear fuselage II for the KC-390 military transport aircraft.

Contract with Messier-Bugatti-Dowty extended to include main landing gear for the Airbus A320.

2013

Aero has entered into a new contract with Italian aircraft manufacturer, Alenia Aermacchi, to supply fuselage panel kits for the Airbus A321.

2014

Aero has started development of the landing gear for the Tecnam P2012 aircraft.

2016

Aero has started production of composite parts and sub-assemblies for the Airbus A400M and A350 for MT Aerospace.

Contract signed with ST Aerospace for the development and production of shell structures for the conversion of Airbus aircraft from transport to freighter.